Al-Shabrami for Factory & Production Line

Relocation and Maintenance

Relocation - Installation - Maintenance

for Factories and Production Lines

نقل المصانع

نقل خطوط الانتاج

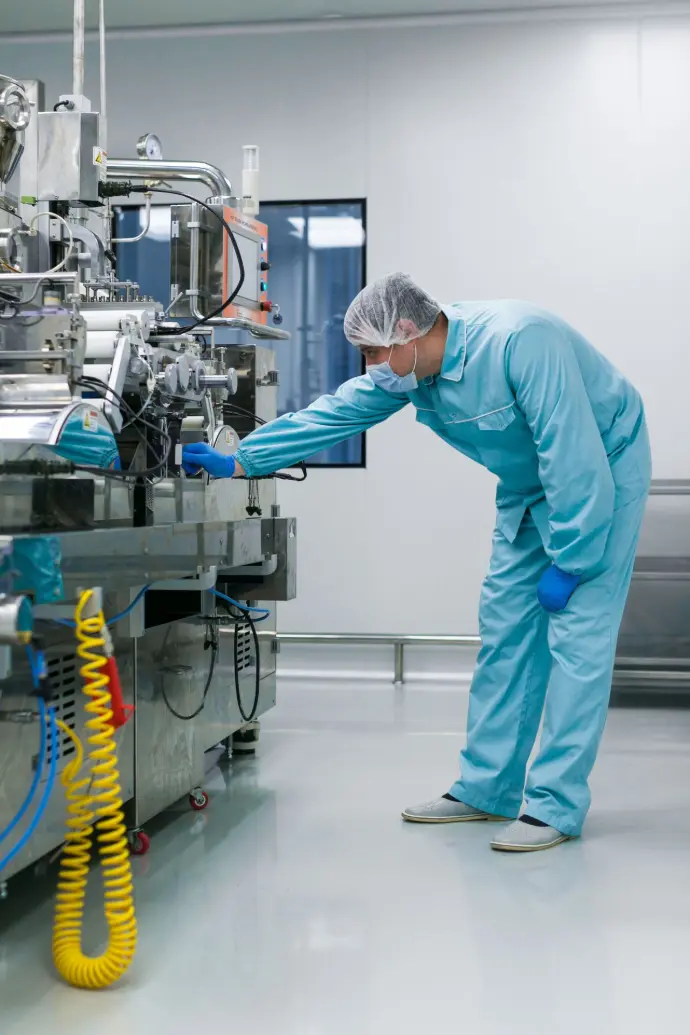

Dismantling, Packaging, Transport, and Installation of Equipment and Production Lines, while Maintaining the Highest Safety Standards

Production Line Installation

A complete installation service that includes mechanical and electrical setup, calibration, testing, and commissioning

صيانه المصانع

صيانة خطوط الإنتاج

Preventive, routine, and emergency maintenance to ensure continuous production and minimize downtime.

We offer comprehensive industrial solutions for the relocation, operation, and maintenance of your factories to the highest standards of quality and safety.

Book Your Appointment Now.

Why Choose Us?

Specialized team, available heavy equipment, extensive experience, reduced downtime, precision, and safety in execution.

01

Specialized Team

A Specialized Technical Team for Heavy Industrial Equipment

02

Heavy Equipment

Commitment to Equipment Safety and Factory Protection

03

Experience

25 Years of Experience in Production Line Relocation and Installation

04

Commitment to Deadlines

Fast Execution and Minimized Downtime

Key Metrics of Our Achievements in Maintenance Services

Our commitment to quality and innovation drives us forward, enabling us to achieve excellence in maintenance services.

Our clients save approximately 30% by choosing our maintenance services.

We take pride in serving over 1,700 satisfied clients throughout our 25 years of experience.

75%

90% of our clients recommend our services to others, reflecting their satisfaction and trust in us.

Frequently Asked Questions (FAQ)

How is an entire factory relocated from one site to another?

Relocating an entire factory from one site to another is one of the most complex industrial processes, as it involves dismantling, transporting, and installing heavy equipment and sensitive production lines. Specialized companies carry out this process through precise steps that ensure equipment safety and minimize production downtime.

1. Site and Equipment Assessment

The process begins with a comprehensive inspection of the old and new factory, analyzing the size and weight of the equipment, determining suitable transport routes, in addition to creating a clear plan for disassembling and numbering each part.

2. Preparing the transportation plan

An engineering timeline plan is developed that includes the arrangement for dismantling equipment, identifying suitable cranes and trucks, preparing safety procedures, and preparing the installation layout at the new factory site.

3. Technical Disassembly of Equipment

The machines and production lines are disassembled carefully, with the mechanical, electrical, and pneumatic connections separated, and then each part is numbered and documented to facilitate reassembly later.

4. Packaging and Protection of Equipment

The equipment is wrapped in protective materials against shocks and moisture, and sensitive devices are placed in special boxes to ensure they are not exposed to any damage during transport.

5. Uploading and Downloading

Using cranes, forklifts, and winches, heavy equipment is lifted and safely loaded onto trucks, with secure fastening to ensure that the equipment does not move during transport.

6. Transfer to the new location

The equipment is transported via dedicated trucks, with full monitoring of the journey and ensuring that all pieces arrive safely at the new location.

7. Unloading and arranging equipment at the new site

The equipment is unloaded and placed in its designated locations according to the plan to ensure a correct sequence for the installation process and the restart of production lines.

8. Installation of Production Lines

The mechanical and electrical assembly processes are repeated, the hydraulic and pneumatic systems are connected, and then the devices are calibrated to return to efficient operation.

9. Testing and Pilot Operation

Before the factory is fully operational, each machine is tested, safety systems are inspected, and performance is adjusted to ensure that the production lines are functioning properly.

10. Delivery of the factory ready for operation

In the end, the factory is delivered to the client along with a complete report on the transportation stages, as well as a maintenance plan to ensure continued operation at high efficiency.

What is the importance of preventive maintenance for production lines?

1. Reducing sudden stops

When equipment is regularly inspected and worn parts are replaced before they fail, the likelihood of breakdowns that completely halt production decreases.

2. Improving Production Efficiency

Well-maintained machines operate smoothly and at peak performance, leading to increased productivity and improved product quality.

3. Reducing repair costs

Preventive maintenance is much cheaper than repairing sudden breakdowns that may require expensive spare parts or urgent technical intervention.

4. Extending the lifespan of equipment

Attention to lubrication, cleaning, calibration, and inspection of critical parts extends the lifespan of equipment for many more years.

5. Improving Occupational Safety

Broken or neglected machines increase the likelihood of accidents and injuries. Preventive maintenance makes the workplace safer.

6. Improving Planning and Production

Since preventive maintenance is performed at predetermined times, the facility can organize operations without unexpected interruptions or losses in the production schedule.

7. Reducing waste and scrap

Uncalibrated machines can cause production errors, while regular maintenance helps maintain consistent quality and reduce defects.

Why choose Al-Shabrami Company to relocate your factory?

If you are looking for a reliable partner to transport your factory or heavy equipment, Al-Shabrami Company is the best choice due to its extensive experience of over 25 years in this field.

Experience that ensures safety

A quarter of a century of experience in factory relocation gives Al-Shabrami the ability to handle various types of equipment, from complex production lines to sensitive equipment that requires special care.

Specialized and qualified team

The company has a highly trained professional team capable of disassembling, assembling, and transporting heavy equipment with precision, ensuring its safety at every stage.

Modern equipment and complete facilities

Al-Shabrami provides low-profile lifts, transport carts, and professional tools that ensure safe and smooth transportation, regardless of the size or weight of the equipment.

Precise planning and quick execution

The transportation process begins with a detailed study of the factory and the transportation route, followed by execution according to a clear plan that ensures the work is completed on time without disrupting production.

Safety and full coverage

Compliance with safety standards and insurance for equipment during transportation is an essential part of the company's operations, reducing risks and protecting your investment.

Fair prices for high quality

Despite the professionalism and advanced equipment, Al-Shabrami offers competitive prices with no hidden costs.

Why do you need an annual maintenance plan?

Having an annual maintenance plan is not a luxury, but a necessity to ensure continued efficient operation and to reduce costs and risks. Here are the main reasons:

1. Preventing sudden failures

خطة الصيانة السنوية في الشبرمي لصيانة خطوط الانتاج تساعد على اكتشاف المشكلات قبل أن تتحول إلى أعطال توقف خطوط الإنتاج أو تتسبب في خسائر كبيرة.

2. Maintaining Equipment Efficiency

Regular inspection, cleaning, and calibration keep the equipment operating at peak performance, which improves product quality and increases productivity.

3. Reducing repair costs

Repairing major breakdowns costs much more than preventive maintenance. The annual plan saves you unexpected expenses.

4. Extending the lifespan of assets

Equipment that is regularly maintained lasts longer and provides consistent performance for years, reducing the need to purchase new equipment.

5. Enhancing Occupational Safety

Regular maintenance reduces the likelihood of accidents caused by faulty or neglected equipment, creating a safer work environment.

6. Better Production Planning

When maintenance is scheduled in advance, you can arrange the production schedule without unexpected interruptions or unplanned downtime.

7. Reducing waste and defects

Uncalibrated equipment may produce defective products. Regular maintenance reduces errors and maintains quality.